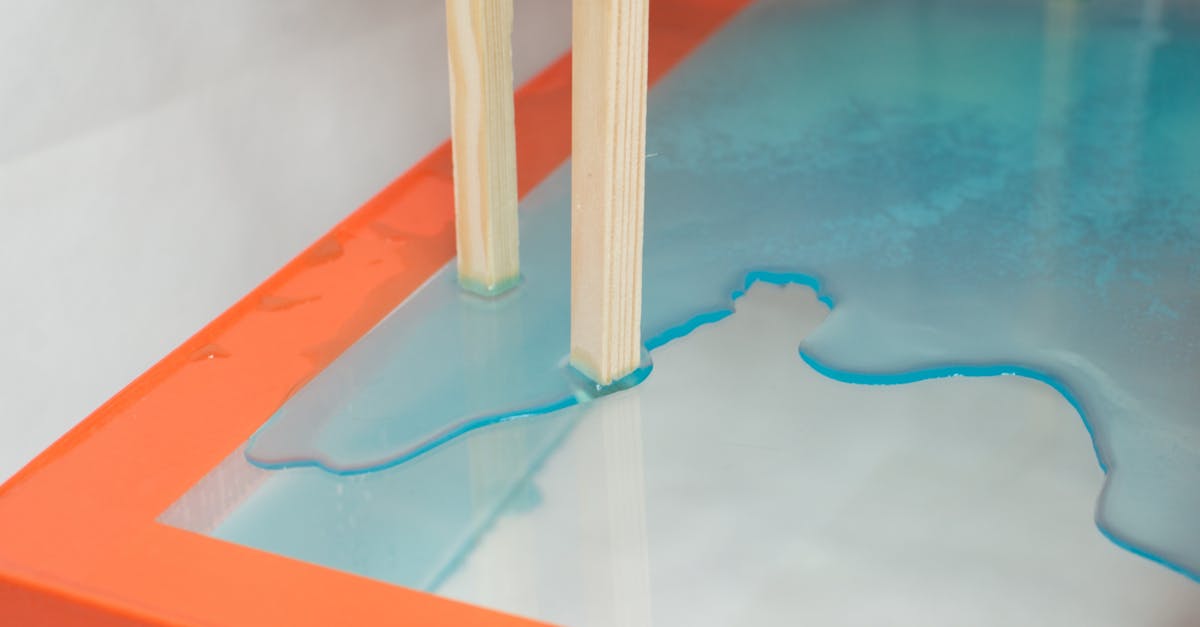

epoxy flooring melbourne

Addressing Seasonal Wear and Tear on Epoxy Floors

When facing significant damage to epoxy floors, professional restoration services can provide the expertise needed to effectively address extensive wear and tear. Specialists use advanced techniques and high-quality materials to restore the surface, ...

Read more →

Adjusting Floor Care Techniques for Melbourne’s Humid Conditions

The high humidity in Melbourne can pose unique challenges for carpet care. Excess moisture in the air increases the risk of mould and mildew growth, making regular cleaning essential. Vacuuming frequently is crucial to remove dirt and debris, which c...

Read more →

Essential Seasonal Checklists for Epoxy Floor Maintenance

Epoxy floors are known for their durability, but certain issues can arise over time. One common problem is the formation of bubbles or blisters, which may occur due to improper installation or moisture trapped beneath the surface. Cracking is another...

Read more →

Protecting Your Epoxy Floor from Melbourne's Rainy Season

Regular inspections play a vital role in maintaining the integrity of your epoxy floor, particularly during Melbourne's rainy season. A systematic approach involves checking for visible wear, such as scratches or discolouration. Inspect joints and se...

Read more →

Seasonal Moisture Control Tips for Epoxy Flooring

Effective air circulation is vital for managing moisture levels in spaces with epoxy flooring. Poor ventilation can lead to dampness, which may compromise the integrity of the epoxy. When air is able to flow freely, it helps to evaporate excess moist...

Read more →

Dealing with Autumn Leaves and Debris on Epoxy Surfaces

As the seasons change, so too do the challenges faced by epoxy surfaces. Autumn brings a cascade of leaves and debris, which can create a sticky mess or make surfaces slippery. Regular inspection during this time is essential to address any build-up ...

Read more →

Effective Spring Clean Strategies for Epoxy Flooring

Stains and spills can pose a significant threat to the appearance of epoxy flooring. Immediate attention is crucial for preserving the surface and preventing permanent discolouration or damage. Begin by blotting up any liquid spills as soon as they o...

Read more →

Preparing Your Epoxy Flooring for Melbourne's Summer Heat

Ensuring that your workspace is adequately ventilated is essential when applying epoxy flooring, especially during the sweltering summer months. Proper airflow helps to dissipate any fumes released during the application process, creating a safer env...

Read more →

Best Practices for Winter Maintenance of Epoxy Floors

Regular inspections of epoxy floors are critical, especially during the winter months. Cold temperatures and increased moisture can impact the integrity of the surface. By routinely examining the floors, it is possible to identify potential issues be...

Read more →

Adapting Your Epoxy Flooring Care Regimen for Melbourne's Varied Seasons

As the weather transitions during autumn, it's essential to adjust your flooring care regimen to protect your epoxy surfaces. Regularly sweeping or vacuuming stubborn leaves, dirt, and other debris can prevent scratches and staining. Ensure to check ...

Read more →

Recommended Products for Stain Removal on Epoxy Floors

Begin by assessing the type of stain and the material involved. Gather the necessary tools and cleaning products based on the stain's nature. For most stains, a soft-bristle brush, microfiber cloth, and a suitable cleaning solution will suffice. Prep...

Read more →

Evaluating Cleaning Products Based on Floor Texture

Eco-friendly cleaning products have gained popularity for their reduced environmental impact. Many of these products use biodegradable ingredients and sustainable packaging. A variety of options cater to different floor textures, ensuring effective c...

Read more →

How to Check Compatibility of Cleaning Products with Epoxy Finishes

When selecting cleaning products for epoxy surfaces, it is important to choose those specifically designed for such finishes. Look for pH-neutral cleaners that gently lift grime without damaging the epoxy surface. Many manufacturers offer products th...

Read more →

Essential Tips for Selecting the Right Floor Wax for Epoxy

Regular maintenance is essential to preserve the appearance and integrity of waxed epoxy floors. Dust and dirt can accumulate quickly, so a routine sweeping or vacuuming will help in preventing scratches and diminishing shine. Use a soft mop with a m...

Read more →

The Importance of Non-Abrasive Cleaners for Epoxy Surfaces

Non-abrasive cleaners offer a gentle yet effective means of maintaining epoxy surfaces, ensuring the integrity and finish of the material are preserved. Unlike abrasive options, which can cause scratches and diminish the aesthetic appeal of the surfa...

Read more →

Top Brands for Epoxy Floor Cleaning Products in Australia

ProTech Cleaners has established itself as a reliable name in the realm of cleaning products aimed at maintaining various flooring types. Their range is particularly noted for effectively addressing the unique needs of epoxy surfaces. This brand offe...

Read more →

Comparing Commercial vs Homemade Cleaning Solutions for Epoxy Flooring

DIY cleaning solutions have gained popularity among homeowners seeking cost-effective and environmentally friendly options. These mixtures often harness the power of common household ingredients, allowing for tailored formulations that suit specific ...

Read more →

The Importance of Regular Maintenance in Epoxy Flooring

When considering the upkeep of epoxy flooring, one option involves hiring professional services. Professionals possess the expertise and equipment necessary to thoroughly assess and maintain the floor's integrity. Their approach often includes specia...

Read more →

Best Eco-Friendly Cleaning Products for Epoxy Flooring in Melbourne

Creating your own cleaning solutions can not only reduce environmental impact but also save money. A simple mixture of white vinegar and water serves as an effective floor cleaner. This natural solution cuts through grime while disinfecting surfaces....

Read more →

How to Select pH-Neutral Cleaners for Epoxy Floors

The growing awareness surrounding environmental issues has led many consumers to think critically about the cleaners they use in their homes and businesses. pH-neutral cleaners provide an eco-friendly alternative since they typically contain fewer ha...

Read more →

How to Protect Your Epoxy Floor from Environmental Damage

Epoxy floors can suffer significant damage when heavy objects are dropped or dragged across the surface. This type of flooring is designed to be durable, yet it may still chip or crack under the weight of furniture, appliances, or tools. It is essent...

Read more →

Best Practices for Moisture Control Under Epoxy Floors

Moisture control is crucial in areas where epoxy flooring is applied. Various environmental factors can influence the effectiveness of the epoxy. High humidity levels can lead to condensation during the installation process, which compromises adhesio...

Read more →

Understanding the Ingredients in Epoxy Floor Cleaners

The effectiveness of epoxy floor cleaners often hinges on their pH levels. A balanced pH range, typically between 6 and 8, is crucial for ensuring that the cleaning agents can effectively break down dirt and grime without damaging the epoxy surface. ...

Read more →

Tips for Preventing Stains and Discolouration on Epoxy Surfaces

Applying protective coatings to epoxy surfaces can significantly enhance their longevity and appearance. These coatings act as a barrier against stains, spills, and scratches, contributing to a more durable finish. The selection of an appropriate sea...

Read more →

Effective Ways to Prevent Wear and Tear on Epoxy Surfaces

Heavy impact can cause significant damage to epoxy surfaces, leading to cracks and chips that compromise their integrity. To minimise the risk of such damage, it's essential to assess the types of activities conducted in areas with epoxy flooring. Im...

Read more →

Routine Inspections: Keeping Your Epoxy Floor in Top Shape

Epoxy floors, while known for their durability and aesthetic appeal, are not immune to certain issues. One common problem is discolouration, which can occur due to prolonged exposure to UV light or harsh chemicals. This can affect both the appearance...

Read more →

Guidelines for Maintaining Floor Integrity Post-Repair

Curing is a vital process that contributes to the overall strength and durability of newly repaired floors. It involves maintaining adequate moisture, temperature, and time to ensure the ultimate development of floor integrity. The specific requireme...

Read more →

Common Mistakes to Avoid in Epoxy Floor Maintenance

One of the most crucial steps in ensuring the longevity of an epoxy floor is proper sealing. Many homeowners mistakenly overlook this essential procedure, believing that a single application of epoxy is sufficient. In reality, an effective seal not o...

Read more →

Essential Preventative Care for Epoxy Flooring in Melbourne

Moisture control plays a crucial role in maintaining the integrity of epoxy flooring. Excessive humidity can lead to adverse effects such as warping, discolouration, and even the development of mould. When epoxy surfaces are installed in environments...

Read more →

Seasonal Checks for Maintaining Epoxy Flooring Durability

As the temperatures begin to drop, it is essential to prepare your epoxy flooring for the autumn season. One of the primary tasks involves clearing away fallen leaves and other debris. Accumulation of organic material can lead to stains or discoloura...

Read more →

Proactive Strategies for Extending the Life of Epoxy Floors

Epoxy flooring is designed to withstand significant weight, but managing heavy loads effectively can prolong its life. Distributing weight evenly across the surface is essential. Using mats or plates can help disperse the load and prevent concentrate...

Read more →

Tips for Matching Epoxy Colour When Making Repairs

When attempting to match epoxy colours for repairs, it is essential to start with a small sample. Mixing a small batch allows for a comparison that can reveal whether the colour is a suitable match for the existing surface. This method helps in ident...

Read more →

When to Seek Professional Help for Epoxy Floor Repairs

Addressing issues in epoxy flooring promptly can prevent more extensive damage and costly repairs down the line. Over time, small cracks or peeling may worsen, leading to structural instability and creating safety hazards. Timely interventions not on...

Read more →

DIY Solutions for Minor Repair Needs in Epoxy Floors

Cracks in epoxy flooring can compromise not only the appearance but also the integrity of the surface. Addressing these issues promptly is essential to maintain a pristine look and prevent further damage. A thorough inspection allows you to identify ...

Read more →

Identifying Common Surface Damage Issues in Epoxy Flooring

Epoxy flooring is known for its durability and aesthetic appeal. However, prolonged exposure to UV rays can lead to noticeable discolouration, altering the original hue of the epoxy. This issue is particularly prominent in areas with direct sunlight,...

Read more →

The Best Tools for Successfully Repairing Epoxy Floors

When working with epoxy floors, safety is paramount. Proper protective gear ensures that you are shielded from hazardous materials and potential accidents during the repair process. Wearing safety goggles helps protect your eyes from splashes and deb...

Read more →

Understanding Different Methods for Epoxy Floor Repair

Floor resurfacing involves the complete removal of existing epoxy layers and any underlying damaged materials. This method restores the floor to a flawless condition, ensuring a solid base for the application of new epoxy. Commonly, this process is r...

Read more →

Step-by-Step Guide to Patching Damaged Epoxy Surfaces

Proper surface preparation is essential for achieving a successful epoxy patch. Begin by cleaning the area thoroughly to remove any dust, dirt, or contaminants. Use a degreaser that is suitable for the substrate. Scrub the surface with a brush to ens...

Read more →

How to Fix Chips and Cracks in Your Epoxy Flooring

Chips and cracks in epoxy flooring can disrupt the surface texture, making restoration essential for a cohesive look. To begin, clean the damaged area thoroughly to remove dirt and debris. This ensures that any materials used for repair will adhere p...

Read more →

Step-by-Step Guide to Routine Maintenance of Epoxy Floors

Regular deep cleaning is essential for maintaining the appearance and longevity of epoxy floors. Begin by removing loose debris with a broom or vacuum. For the next stage, prepare a solution of warm water and a pH-neutral cleaner designed for epoxy s...

Read more →

Effective Techniques for Repairing Scratches in Epoxy Floors

Minor scratches on epoxy floors can often be treated without the need for professional intervention. One effective technique involves using sandpaper to smooth out the affected area. Start with a fine-grit sandpaper, ideally around 1500 to 2000 grit,...

Read more →

How to Handle Spills on Epoxy Flooring

To effectively minimise the risk of spills on epoxy flooring, it is essential to focus on proper maintenance and cleanliness. Regularly sweeping or vacuuming the surface helps prevent dirt and debris from mixing with spills, making them harder to cle...

Read more →

Eco-Friendly Cleaning Methods for Epoxy Flooring

When selecting tools for eco-friendly cleaning, it's important to opt for those made from sustainable materials. Bamboo brushes and biodegradable sponges effectively tackle dirt without harming the environment. Microfiber cloths also serve as a great...

Read more →

Mistakes to Avoid When Cleaning Epoxy Surfaces

The use of abrasive tools on epoxy surfaces can lead to significant damage. Scratches and dullness may occur, compromising both appearance and functionality. These surfaces require a gentle touch to maintain their integrity while ensuring they remain...

Read more →

Choosing the Right Tools for Maintaining Epoxy Floor Cleanliness

Deep cleaning an epoxy floor requires a systematic approach to ensure the surface remains pristine and durable. Start by removing loose debris and dust with a broom or vacuum designed for hard surfaces. Next, prepare a cleaning solution suitable for ...

Read more →

How to Remove Stains from Epoxy Floors Safely

Epoxy floors can often bear light stains from spills and daily wear. Addressing these stains promptly helps maintain the floor’s appearance. Start by sweeping or vacuuming the area to remove loose debris. Next, mix a gentle cleaning solution using ...

Read more →

Effective Techniques to Maintain the Shine of Epoxy Flooring

Placing mats and rugs strategically throughout spaces featuring epoxy flooring can significantly contribute to the longevity and appearance of the surface. These barriers help to catch dirt, dust, and moisture before they reach the epoxy, reducing th...

Read more →

Best Practices for Regularly Cleaning Epoxy Floors

Stains on epoxy floors can occur due to various substances, such as oil, food, or chemical spills. Immediate action is crucial to minimise the potential for lasting damage. Start by blotting up any liquid spills with a clean cloth or paper towel. For...

Read more →

The Ultimate Guide to Everyday Cleaning Solutions for Epoxy Floors

When it comes to maintaining an epoxy floor, having the right tools can make all the difference. A soft-bristle broom is ideal for daily sweeping, as it effectively removes dust and debris without scratching the surface. For deeper cleaning, a microf...

Read more →

Frequency Recommendations for Cleaning Your Epoxy Flooring

Regular maintenance of epoxy flooring throughout the seasons will help maintain its appearance and durability. During the spring, it’s beneficial to conduct a thorough cleaning after the wet season. This includes removing any accumulated dirt or de...

Read more →

Ensuring Safe Mixing Practices for Epoxy Resins

Proper storage of epoxy resins is crucial for maintaining their effectiveness and safety. These materials should be kept in a cool, dry area away from direct sunlight and excessive heat. High temperatures can accelerate the curing process too quickly...

Read more →

Electrical Safety Measures When Working with Epoxy Products

When working with epoxy products, it is crucial to prioritise safety to prevent accidents and health risks. Always wear appropriate personal protective equipment (PPE) including gloves, goggles, and respirators to safeguard against harmful skin conta...

Read more →

Assessing Environmental Conditions Before Installation

Before initiating any installation project, it's crucial to familiarise oneself with local regulations and compliance requirements. These guidelines are established by governmental authorities to ensure that projects adhere to safety, environmental, ...

Read more →

Handling Epoxy Chemicals Safely: Key Guidelines

Prompt action is crucial following a spill of epoxy chemicals. The first step involves immediately assessing the spill to determine its size and whether it poses a risk to health or safety. Ensure that all personnel are evacuated from the area if nec...

Read more →

Best Practices for Ventilation During Epoxy Floor Application

Ensuring a safe environment during epoxy floor application involves careful monitoring of air quality. Contaminants released during the mixing and application processes can pose risks to health. Regular checks for volatile organic compounds (VOCs) pr...

Read more →

The Role of First Aid Knowledge in Epoxy Flooring Projects

The use of protective gear is essential for anyone engaged in epoxy flooring projects. This type of work often involves exposure to chemicals, dust, and equipment that can lead to potential injuries. Items such as gloves, safety goggles, and respirat...

Read more →

Importance of Non-Slip Footwear When Installing Epoxy Floors

The effectiveness of non-slip footwear directly influences the productivity levels of workers engaged in epoxy flooring installation. When workers feel secure in their footing, their ability to focus on the task at hand improves significantly. This r...

Read more →

Emergency Procedures for Accidents During Installation

It is essential to establish clear evacuation protocols prior to the commencement of any installation project. All personnel must be informed of designated escape routes and assembly points. Regular drills should be conducted to ensure that everyone ...

Read more →

Identifying and Mitigating Hazards in the Epoxy Flooring Workspace

Conducting a risk assessment is a crucial step in ensuring safety in the epoxy flooring workspace. This process involves identifying potential hazards associated with the materials and activities involved in epoxy flooring projects. A thorough evalua...

Read more →

Assessing Curing Time for Various Epoxy Flooring Types

This type of epoxy is designed to achieve a balance between strength, ease of application, and curing efficiency. It typically sets within a standard timeframe of 7 to 14 days, depending on the environmental conditions and the specific product formul...

Read more →

Understanding Personal Protective Equipment for Epoxy Flooring Installation

Choosing the right footwear is essential for anyone involved in epoxy flooring installation. Safety boots with slip-resistant soles provide necessary traction on potentially slick surfaces, reducing the risk of falls. Additionally, boots should be wa...

Read more →

Importance of Ventilation During the Curing of Epoxy Floors

A noticeable increase in odours during the epoxy curing process can be an early indicator of inadequate ventilation. Strong chemical smells not only signal that vapours are accumulating but also suggest that the gas by-products from the curing epoxy ...

Read more →

Troubleshooting Curing Issues in Epoxy Flooring Applications

Proper environmental conditions play a crucial role in the curing process of epoxy flooring. Temperature and humidity directly affect the rate at which the epoxy sets and hardens. Ideally, the ambient temperature should be maintained between 15°C an...

Read more →

Recommended Curing Conditions for Different Epoxy Products

Fast-curing epoxy products are designed to set quickly while maintaining strong adhesion and durability. These formulations are ideal for projects requiring rapid finishing times, often used in construction and automotive applications. The unique ble...

Read more →

Common Mistakes When Curing Epoxy Floors and How to Avoid Them

The timing of application is crucial when working with epoxy floors. It is essential to ensure that the products are mixed and applied within the recommended timeframe. Temperatures can greatly affect how quickly the epoxy sets. If the temperature is...

Read more →

Impact of Temperature on Epoxy Floor Curing in Melbourne

Low temperatures can significantly hinder the curing process of epoxy floors. These conditions often result in an extended curing time, leading to incomplete polymerisation. This can affect the floor’s final strength and adhesion, resulting in a su...

Read more →

Best Practices for Monitoring Curing Times of Epoxy Installations

Evaluating the cure of epoxy is essential for ensuring its structural integrity and performance. One of the most common testing methods is the durometer hardness test. This technique involves pressing a durometer gauge into the epoxy surface to measu...

Read more →

How Humidity Affects the Curing Process of Epoxy Flooring

In environments with low humidity, the epoxy curing process can be significantly affected. Drier air accelerates the evaporation of solvents within the epoxy mixture. This rapid evaporation may lead to various issues such as incomplete curing, which ...

Read more →

Understanding Curing Times for Epoxy Flooring in Melbourne

The first step in applying epoxy flooring involves preparing the surface thoroughly. This process begins with cleaning the floor to eliminate dust, debris, and any existing coatings. Repairs should be made to concrete cracks or imperfections. Ensurin...

Read more →

Factors Influencing Curing Conditions for Epoxy Floors

Effective surface preparation is crucial for achieving the best results when applying epoxy floors. The surface should be thoroughly cleaned to remove any dust, grease, or contaminants that could hinder adhesion. Methods such as shot blasting, diamon...

Read more →

Evaluating Different Application Techniques for Epoxy Flooring

When comparing application techniques for epoxy flooring, the method of application can significantly impact both coverage and overall finish. Rollers, for example, typically offer a quicker application process, allowing more substantial coverage ove...

Read more →

Tips for Using Roller and Trowel in Epoxy Application

Using a roller is one of the most efficient methods for applying epoxy, especially in larger areas where speed and coverage are essential. Begin by selecting the right type of roller, as a short nap is often preferable for a smooth finish. Ensure the...

Read more →

Creating Textured Finishes with Epoxy Application Methods

Epoxy resin offers endless possibilities for creating stunning designs that cater to individual tastes. By incorporating various techniques such as layering colours, adding metallic powders, or introducing natural elements like leaves and stones, art...

Read more →

Essential Timing for Epoxy Mixing and Application Cycles

Understanding the curing times of various epoxy types is crucial for achieving optimal results in any project. Standard epoxy resins often cure within 24 hours, reaching their full strength after about seven days. Fast-curing epoxies significantly re...

Read more →

How Temperature Affects Epoxy Mixing and Application

Temperature plays a crucial role in determining how easily epoxy will mix and cure. Warm conditions can accelerate the setting process, making it imperative to blend the components quickly to avoid premature hardening. Conversely, colder temperatures...

Read more →

Common Mistakes in Epoxy Mixing and How to Avoid Them

Pot life refers to the period during which mixed epoxy remains workable before it starts to harden. Manufacturers provide this information for their specific resin and hardener combinations, helping users understand how long they can manipulate the m...

Read more →

Techniques to Achieve a Smooth Epoxy Application

Achieving a smooth finish with epoxy requires careful planning and specific techniques throughout the application process. Preparation of the surface is crucial. This includes cleaning, sanding, and ensuring the surface is entirely dust-free to promo...

Read more →

Best Practices for Mixing Two-Part Epoxy Solutions

Achieving the right mixing conditions is essential for the successful application of two-part epoxy solutions. The environment in which the mixing occurs plays a significant role in determining the quality of the final product. Ideally, the temperatu...

Read more →

Understanding the Epoxy Mixing Process for Optimal Results

Pot life refers to the period during which mixed epoxy resin remains usable before it begins to harden. This timeframe can significantly impact the effectiveness of the application process. Factors such as temperature and the proportions of resin to ...

Read more →

Step-by-Step Guide to Applying Epoxy on Floors

Before beginning, ensure the floor surface is clean, dry, and free from any contaminants. Pour the epoxy mixture onto the floor in sections. Use a roller to spread the epoxy evenly, working in rows to cover the entire area. Maintain a consistent pres...

Read more →

Creating a Dust-Free Environment for Epoxy Installation

Dust can lead to unwanted imperfections in epoxy surfaces. To mitigate this risk, it’s essential to create a physical barrier that restricts airborne particles from entering the work area. Sealing doors and windows can be highly effective. Using we...

Read more →

The Significance of Temperature Control in Substrate Preparation

Effective temperature monitoring requires a systematic approach to ensure optimal conditions. Regularly calibrating temperature sensors helps maintain accuracy in readings. Using multiple sensors throughout the substrate area allows for a more compre...

Read more →

Best Practices for Grinding and Scarifying Concrete Floors

Concrete grinding requires the right choice of equipment to achieve optimal results. Using a heavy-duty grinder with diamond blades designed for the specific type of concrete can significantly enhance efficiency. Keep a steady pace during the grindin...

Read more →

Understanding the Importance of Surface Profile for Epoxy Bonding

Achieving an optimal surface profile is vital for ensuring strong epoxy bonding. One common approach involves employing abrasive methods such as sanding, grinding, or shot blasting. These techniques effectively remove contaminants and create a textur...

Read more →

Tools for Efficient Substrate Preparation in Epoxy Flooring

The importance of maintaining a clean work environment in epoxy flooring projects cannot be overstated. Dust and debris can significantly affect the adhesion and overall finish of the epoxy resin. Implementing a high-quality vacuum system during subs...

Read more →

How to Remove Old Coatings Before Applying Epoxy

Mechanical tools play a crucial role in the efficient removal of old coatings. Options such as grinders, sanders, and scrapers can significantly expedite the process, especially for large surfaces. When selecting these tools, consider their compatibi...

Read more →

The Role of Patching and Repairing in Substrate Preparation

Patching is often met with various obstacles that can significantly hinder the repair process. One common challenge involves the compatibility of patching materials with existing substrates. If materials do not bond effectively, it can lead to delami...

Read more →

Evaluating Moisture Levels in Concrete for Epoxy Flooring

Elevated moisture levels in concrete can reveal themselves through various visual indicators. One common sign is efflorescence, which manifests as a white, powdery substance on the surface. This occurs when water evaporates from the concrete, leaving...

Read more →

Assessing the Condition of Concrete Before Epoxy Installation

The thickness of concrete plays a crucial role in the successful installation of epoxy coatings. A consistent thickness ensures that the epoxy adheres properly and performs as intended. Generally, concrete slabs should be a minimum of 100 millimetres...

Read more →

Essential Steps for Cleaning Your Substrate Prior to Application

Preparing your substrate for application involves a comprehensive cleaning process that removes impurities and contaminants. This stage is crucial, as any residual dirt or debris can compromise adhesion and affect the durability of the final product....

Read more →

Choosing the Right Squeegees and Rollers for Epoxy Applications

Different squeegee sizes and shapes cater to various project needs. A broad squeegee can cover large surface areas efficiently, making it ideal for expansive flooring jobs. Conversely, smaller squeegees are more suited for detailed work, allowing for...

Read more →

Top Equipment Recommendations for Epoxy Flooring Projects

When it comes to preparing concrete surfaces for epoxy flooring, heavy-duty flooring grinders are essential tools. These grinders effectively remove imperfections, adhesives, and old coatings, ensuring a smooth and clean substrate. Many models come e...

Read more →

Innovative Tools to Streamline Epoxy Floor Installation

Precision is critical during the installation of epoxy floors. Utilising high-quality measuring tools such as laser levels and tape measures ensures accurate dimensions for both the space and the materials required. Laser levels provide a clear and p...

Read more →

Necessary Equipment for Preparing the Epoxy Flooring Project

Selecting the right finishing tools is essential for achieving the desired outcome in an epoxy flooring project. A good quality squeegee plays a critical role in spreading the epoxy evenly across the surface. It helps eliminate air bubbles and ensure...

Read more →

Key Tools for Achieving a Flawless Epoxy Floor Finish

Achieving a perfectly level surface is crucial for a successful epoxy floor application. One of the primary tools for this task is a screed, which allows for the even distribution of the epoxy mixture across the floor. A straight edge can also be uti...

Read more →

Best Practices for Selecting the Right Installation Equipment

Selecting installation equipment requires careful assessment of how well it integrates with your current systems. It's crucial to evaluate technical specifications and functionalities. Misalignments can lead to significant operational issues and incr...

Read more →

Must-Have Gear for Successful Epoxy Flooring Installation

Accurate measurements form the foundation for a successful epoxy flooring installation. To achieve precise dimensions, reliable measuring tools are essential. A high-quality tape measure ensures that lengths and widths are correctly gauged, while a l...

Read more →

Comprehensive Guide to Epoxy Flooring Installation Tools

Achieving a polished finish on epoxy flooring requires specific tools designed for that final touch. Trowels and spatulas are essential for smoothing out the surface and ensuring an even application of the epoxy resin. These tools can help eliminate ...

Read more →

Understanding Equipment Required for Epoxy Floor Application

When applying epoxy floors, selecting the right tools is essential for achieving a smooth and durable finish. The most common application methods involve the use of trowels and squeegees, which help to evenly distribute the epoxy across the surface. ...

Read more →

Essential Tools for Installing Epoxy Flooring in Melbourne

Preparing the surface correctly is essential for a successful epoxy flooring installation. Begin by cleaning the area thoroughly, removing any dust, grease, or debris that could affect adhesion. If there are imperfections like cracks or holes, these ...

Read more →

Environmental Benefits of Using Anti-Slip Epoxy Flooring

Epoxy flooring is inherently resistant to stains and spills, making it easy to maintain a high level of cleanliness in various environments. Its seamless surface prevents the accumulation of dirt and bacteria, which is particularly beneficial in spac...

Read more →

The Role of Texture in the Effectiveness of Anti-Slip Epoxy Flooring

Maintaining textured epoxy floors requires regular cleaning to ensure their longevity and effectiveness. Debris and spills can accumulate in the grooves and patterns of the texture, potentially leading to slippery conditions if not addressed promptly...

Read more →

Maintenance Requirements for Long-Lasting Anti-Slip Epoxy Flooring

The integrity of anti-slip epoxy flooring can be seriously compromised by harsh chemicals. Common cleaning agents, solvents, and industrial chemicals pose risks that can lead to discolouration, fading, or even structural damage. It is crucial to choo...

Read more →

Common Mistakes to Avoid When Installing Anti-Slip Epoxy Flooring

Proper ventilation is crucial when installing anti-slip epoxy flooring. It allows for the dispersal of potentially harmful vapours produced by the epoxy resin and hardener. When these products are mixed and applied, they emit fumes that can be irrita...

Read more →

Comparing Anti-Slip Epoxy Flooring to Other Slip-Resistant Options

The installation of anti-slip epoxy flooring involves several crucial steps that need careful execution. Preparation of the surface is essential, requiring cleaning and possibly repairing any damage to ensure optimal adhesion of the epoxy. Once the s...

Read more →

Installation Tips for Anti-Slip Epoxy Flooring in Wet Areas

The success of anti-slip epoxy flooring in wet areas largely hinges on achieving strong adhesion between the substrate and the epoxy layer. To maximise bonding, surfaces must be thoroughly cleaned and free from contaminants such as dust, oils, and mo...

Read more →

Top Design Trends in Anti-Slip Epoxy Flooring for 2023

Injecting custom artwork into anti-slip epoxy flooring transforms spaces with personal flair and creativity. Clients are increasingly seeking design solutions that reflect their identity and values. This trend allows for the incorporation of original...

Read more →

Choosing the Right Anti-Slip Epoxy for Your Home Environment

When selecting an anti-slip epoxy for your home, it is essential to consider established safety standards. Various organisations, including local and international bodies, have developed guidelines to ensure materials provide adequate grip and minimi...

Read more →

How Anti-Slip Epoxy Flooring Improves Safety in Commercial Spaces

The application of anti-slip epoxy flooring begins with thorough surface preparation. This step involves cleaning the area to remove any dust, dirt, or oil, which ensures a strong bond between the epoxy and the substrate. Any cracks or imperfections ...

Read more →

Benefits of Anti-Slip Epoxy Flooring in High-Traffic Areas

Businesses operating in high-traffic areas rely on surfaces that provide safety and stability underfoot. Anti-slip epoxy flooring is specifically designed to enhance traction, reducing the risk of slips and falls. The textured finish of this type of ...

Read more →

How to Achieve a Perfect Finish with Self-Leveling Epoxy

To achieve the best results with self-leveling epoxy, it's crucial to consider the environment during application. The ideal temperature range typically falls between 15°C and 25°C. High humidity levels can also affect the curing process, leading t...

Read more →

Understanding the Self-Leveling Epoxy Installation Timeline

Before applying self-leveling epoxy, it is essential to prepare the surface thoroughly. This includes cleaning, repairing cracks, and ensuring the substrate is dry and free of contaminants. The area should be well-ventilated to facilitate the curing ...

Read more →

Colour Options and Aesthetics of Self-Leveling Epoxy Flooring

The popularity of self-leveling epoxy flooring has surged in recent years, driven by a desire for both aesthetic appeal and functional durability. Homeowners and businesses alike appreciate the sleek appearance and seamless finish that these floors p...

Read more →

The Environmental Impact of Self-Leveling Epoxy Flooring

The lifespan of epoxy flooring typically ranges from 10 to 20 years. As these surfaces age, their structural integrity may decline. Maintenance can prolong their usability, yet eventual deterioration is unavoidable. Once the flooring reaches a point ...

Read more →

Ideal Applications for Self-Leveling Epoxy in Melbourne

Self-leveling epoxy provides a seamless and smooth finish that traditional flooring options often lack. Unlike tiles or vinyl, which can leave gaps or joints, epoxy creates a solid surface that is not only visually appealing but also functional. This...

Read more →

Cost Comparisons: Self-Leveling Epoxy vs Traditional Flooring

The application process for self-leveling epoxy involves several specific steps to achieve a smooth, durable surface. Initially, the floor must be thoroughly cleaned and prepared, which may include grinding or shot-blasting to remove any existing coa...

Read more →

How Self-Leveling Epoxy Flooring Enhances Commercial Properties

The application of self-leveling epoxy flooring begins with thorough surface preparation. This step is crucial to ensure proper adhesion and durability of the final finish. Firstly, the existing floor must be cleaned meticulously to remove any dirt, ...

Read more →

Common Misconceptions About Self-Leveling Epoxy Flooring

Proper maintenance of self-leveling epoxy flooring is often simpler than many assume. Regular cleaning with a broom or damp mop typically suffices to keep the surface looking fresh. Occasionally, a specialised cleaner may be necessary to address toug...

Read more →

Key Characteristics of High-Quality Self-Leveling Epoxy Systems

Applying self-leveling epoxy requires meticulous preparation and precise techniques. The substrate must be clean, dry and adequately primed. Poor surface conditions can hinder adhesion, leading to premature failure of the flooring system. Selecting t...

Read more →

Benefits of Self-Leveling Epoxy Flooring for Residential Spaces

Self-leveling epoxy flooring offers exceptional resistance to various chemicals and stains, making it an excellent choice for residential environments. This feature proves particularly advantageous in homes where spills from household cleaners, oils,...

Read more →

Realising the Versatility of Metallic Epoxy in Different Settings

Metallic epoxy offers a unique aesthetic that can enhance any space, combining functionality with striking visuals. The range of colours and finishes available allows for personal expression, making it suitable for both commercial and residential set...

Read more →

Maintenance Essentials for Long-lasting Metallic Epoxy Floors

Regular maintenance is crucial for extending the life of metallic epoxy floors through the changing seasons. During autumn, it’s essential to sweep away fallen leaves and debris which can become trapped and cause discolouration over time. A damp mo...

Read more →

Exploring the Colour Options Available for Metallic Epoxy Flooring

Several techniques can be employed to achieve stunning colour effects with metallic epoxy flooring. Using a spray technique allows for a more uniform distribution of metallic pigments across the surface. This method enables an even blend of colours a...

Read more →

How Metallic Epoxy Flooring Enhances Commercial Spaces

Metallic epoxy flooring stands out as a sustainable solution for environmentally conscious businesses. Made from recycled materials, this type of flooring not only minimises waste but also contributes to a reduction in the carbon footprint. Utilising...

Read more →

Installation Tips for Achieving a Flawless Metallic Epoxy Finish

Temperature and humidity play a crucial role in the application of metallic epoxy. Ideal conditions typically range between 18°C to 24°C. Humidity should be kept below 60% to ensure proper curing and adhesion. When the environment is too cold or to...

Read more →

Comparing Metallic Epoxy with Other Flooring Options

Various flooring options come with unique maintenance needs. Metallic epoxy is relatively low-maintenance when compared to materials like natural stone or hardwood. Regular cleaning involves sweeping or vacuuming to remove dust and debris, followed b...

Read more →

Trends in Metallic Epoxy Flooring Designs for Modern Interiors

Metallic epoxy flooring has gained traction in various commercial settings due to its unique aesthetic appeal and functional benefits. Retail shops, restaurants, and galleries are increasingly adopting this flooring option to create striking environm...

Read more →

How to Choose the Right Metallic Epoxy Finish for Your Space

The choice of supplier plays a crucial role in the success of your metallic epoxy project. When searching for a vendor, consider their experience and reputation within the industry. Look for companies that have a strong track record of delivering hig...

Read more →

Understanding the Benefits of Metallic Epoxy Applications

Metallic epoxy coatings offer a wide range of applications across various industries. They are often utilised in residential, commercial, and industrial settings, thanks to their aesthetic appeal and durability. From art galleries to restaurants, the...

Read more →

The Dazzling Appeal of Metallic Epoxy Flooring in Melbourne Homes

The use of metallic epoxy flooring presents an increasingly appealing option for homeowners who are conscious of their environmental impact. Its longevity reduces the need for frequent replacements, which contributes to less waste in landfills. Moreo...

Read more →

Comparing Flake Epoxy to Other Decorative Flooring Options

Flake epoxy flooring and polished concrete each bring unique advantages to residential and commercial spaces. Flake epoxy offers a wide range of colours and styles, allowing for customisation that can align with various design themes. Its textured su...

Read more →

The Cost-Effectiveness of Flake Epoxy Flooring Solutions

The installation of flake epoxy flooring begins with thorough surface preparation. This crucial step involves cleaning and repairing the concrete slab. Any cracks or imperfections must be addressed to ensure a smooth final surface. After cleaning, a ...

Read more →

How Flake Epoxy Flooring Can Improve Indoor Air Quality

Flake epoxy flooring is known for its exceptional durability and longevity, making it a preferred choice in both residential and commercial settings. The robust nature of the materials used ensures that it can withstand significant wear and tear, fro...

Read more →

Common Mistakes to Avoid When Applying Flake Epoxy

Achieving the right application thickness is crucial for the success of flake epoxy projects. Applying too thick a layer can lead to a number of issues including uneven drying and the potential for sagging. It also increases the likelihood of bubbles...

Read more →

Enhancing Durability with Quality Flake Epoxy Products

Regular cleaning is essential to maintain the appearance and longevity of flake epoxy surfaces. Sweep or vacuum the area frequently to remove dirt and debris that could scratch the finish. For deeper cleaning, use a pH-neutral cleaner mixed with warm...

Read more →

Colour Combinations and Aesthetics in Flake Epoxy Flooring

Flake epoxy flooring offers a plethora of customisation options, allowing homeowners and businesses to create a unique aesthetic tailored to their spaces. Various colours and flake sizes can be combined to achieve a distinct look that reflects person...

Read more →

How to Choose the Right Flake Size for Your Epoxy Floor

Selecting the appropriate installation technique is essential for achieving the desired aesthetic and functionality when working with different flake sizes. When using larger flakes, such as those measuring 10mm or more, it's important to apply a thi...

Read more →

Installing Flake Epoxy Flooring: A Step-by-Step Guide

Incorporating flakes into the epoxy coating enhances both aesthetics and texture. It is essential to select the right type and size of flakes for the desired finish. Ensure the basecoat is still tacky when adding the flakes, which helps them adhere p...

Read more →

Benefits of Flake Epoxy Flooring for Residential Spaces

The installation of flake epoxy flooring begins with thorough surface preparation. This involves cleaning the concrete substrate to remove any dirt, grease, and old coatings. Any cracks or imperfections in the concrete are repaired to ensure a smooth...

Read more →

Design Options for Flake Epoxy Flooring in Commercial Areas

Regular maintenance is essential to ensure the longevity and appearance of flake epoxy flooring in commercial spaces. Daily sweeping or vacuuming helps remove dirt and debris that could scratch the surface. For deeper cleaning, a damp mop with a pH-n...

Read more →

Innovative Applications of Solid Epoxy Flooring in Commercial Spaces

The demand for environmentally responsible materials continues to rise, and solid epoxy flooring stands out as a sustainable choice. This flooring is not only durable but also made from materials that can significantly reduce waste. Many manufacturer...

Read more →

Environmental Impact of Solid Epoxy Flooring Materials

The shift towards sustainable practices in the construction and flooring industries has prompted a growing interest in sourcing environmentally friendly materials for epoxy flooring. Manufacturers now seek bio-based epoxies or those made from recycle...

Read more →

The Best Solid Epoxy Flooring Brands Available in Australia

The installation of solid epoxy flooring requires careful preparation and precision to achieve optimal results. Begin by evaluating the surface where the epoxy will be applied, ensuring it is clean, dry, and free from debris. Any cracks or imperfecti...

Read more →

Installation Challenges of Solid Epoxy Flooring

Timely project completion is often a critical factor in flooring installations. Solid epoxy flooring systems typically require meticulous preparation and application processes. If any part of the project timeline is underestimated or disrupted, it ca...

Read more →

Durability and Longevity of Solid Epoxy Flooring Explained

Solid epoxy flooring stands out in comparison to other popular flooring choices such as vinyl and tile. Vinyl flooring is often praised for its affordability and ease of installation, making it a common choice for residential spaces. However, it tend...

Read more →

Comparing Solid Epoxy Flooring to Other Flooring Types

Many industrial facilities rely on flooring solutions that can withstand the rigours of heavy machinery and frequent foot traffic. Solid epoxy flooring offers exceptional durability, making it resistant to wear and tear even in the most demanding env...

Read more →

Cost Analysis of Installing Solid Epoxy Flooring in Melbourne

When planning for a solid epoxy flooring installation, it is essential to account for additional installation fees that may arise. These costs can include substrate preparation, which might involve cleaning, repairing, or levelling the concrete surfa...

Read more →

Solid Epoxy Flooring: A Guide to Design and Colour Choices

Solid epoxy flooring application requires careful preparation of the substrate. Begin by ensuring the surface is clean, dry and free from contaminants. Any existing coatings should be removed to ensure proper adhesion. For concrete surfaces, a thorou...

Read more →

How to Choose the Right Solid Epoxy for Your Space

When considering the application of solid epoxy, there are several methods to choose from. Rollers are a popular option for larger areas, allowing for even coverage and a smooth finish. Spraying can achieve a professional look but requires more skill...

Read more →

Benefits of Solid Epoxy Flooring for Melbourne Homes

The thermal mass of solid epoxy flooring provides significant benefits in maintaining comfortable indoor temperatures throughout the year. It absorbs heat during the warmer months and releases it during cooler periods, creating a more stable environm...

Read more →